Palm Leaf

Palm Leaf

The truly sustainable choice

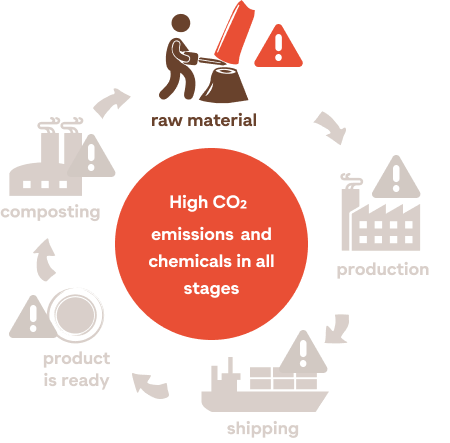

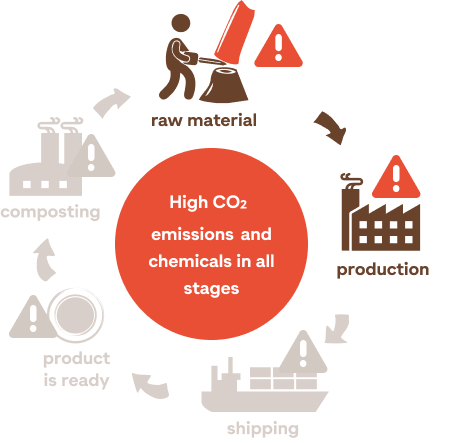

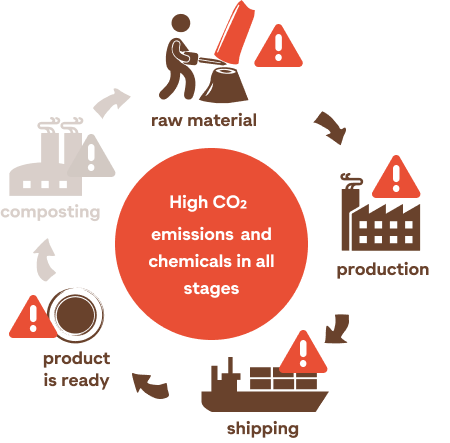

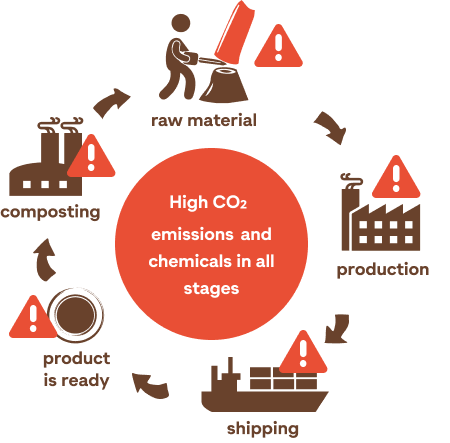

When it comes to disposable tableware, materials like plastic, paper, aluminum, and bioplastics come with a heavy environmental cost: high carbon emissions, lots of recycling issues, and piles of waste.

Palm leaf is the game-changer!

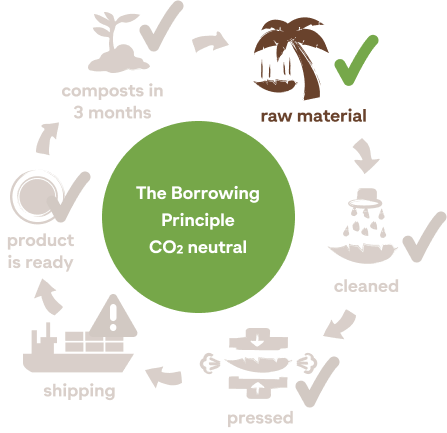

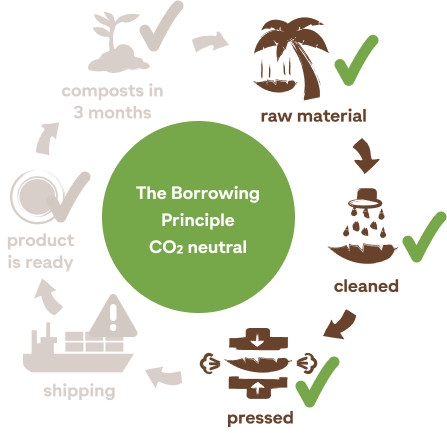

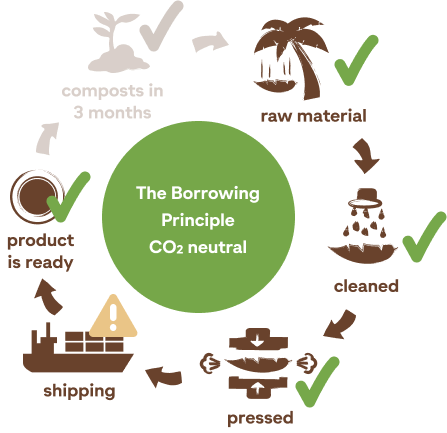

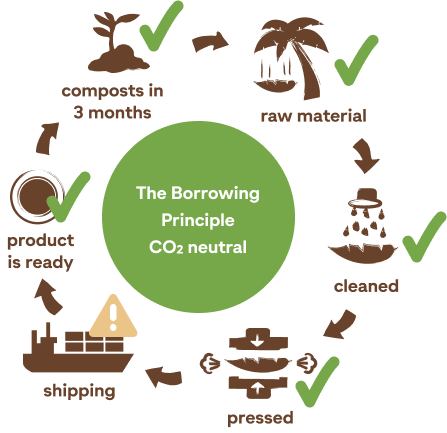

Life cycle – Palm leaf vs other materials

Life cycle – Palm leaf vs other materials

Climate neutrality and circularity of palm leaf compared to other eco-friendly materials.

Palm Leaf

Palm leaf offers a fully circular and climate-neutral life cycle. Naturally shed from Areca palm trees without any need for cultivation or pesticides, the leaves are gathered and processed using low-energy methods powered by renewable resources. After use, they break down naturally, adding nutrients to the soil. Palm leaf retains the carbon absorbed during growth and, when composted, even becomes CO₂-negative, enhancing soil health.

Paper, bioplastics & co

Materials like paper, bioplastics, sugarcane bagasse and bamboo are often marketed as sustainable, but they all face several climate problems. A carbon-intensive production with energy- and water-heavy processes and often chemical treatments for durability. They mostly don’t compost into beneficial soil but rather become inert biomass, without ecological value. Bagasse mainly contains harmful PFAS chemicals, paper often needs coatings, making it unrecyclable and toxic.

Raw Material

Palm leaf offers a fully circular and climate-neutral life cycle. Naturally shed from Areca palm trees without any need for cultivation or pesticides, the leaves are gathered and processed using low-energy methods powered by renewable resources. After use, they break down naturally, adding nutrients to the soil. Palm leaf retains the carbon absorbed during growth and, when composted, even becomes CO₂-negative, enhancing soil health.

Processing

The leaf reshaping process utilizes small machines primarily powered by renewable energy sources such as hydro, wind, and solar. LEEF is working on expanding its solar capacity to ensure production relies solely on renewable energy. Due to the natural lotus effect of leaves, palm leaf needs no coating or chemicals to be stable und resistant to liquids. As no chemicals are used, the water does not need to be purified after production, and it is suitable for direct agricultural use.

Shipping

The only carbon emissions associated with palm leaf products comes from shipping them from India to their destination. By keeping shipping to a single journey and using renewable energy wherever possible, we minimize emissions and keep costs low. There’s no need for additional resource shipping, making this a streamlined, sustainable solution.

Disposal

Palm leaf products effortlessly decompose in all composting scenarios — natural, home, and industrial. Palm leaves retain the carbon absorbed during growth when composted, and even become CO₂-negative, enhancing soil health. Palm leaf also decomposes into healthy compost, unlike synthetic materials like bagasse or bioplastics, which become inert biomass. This makes palm leaf an excellent addition to composting plants, especially where other ‘‘compostable’’ materials are often sorted out.

Raw Material

One problem all other eco-friendly materials have in common is, that they need a lot of resources and energy during production process. This often brings higher emissions than the entire life cycle of palm leaf, including transport. A lot of bioplastics rely on fossil fuels as raw materials. Turning raw bamboo into fabric or paper also requires significant energy and chemicals.

Processing

The processing of these materials usually involves huge industrial plants with high energy and water consumption. The fermentation and polymerization processes in bioplastic production also consume large amounts of water. The use of chemicals like bleaching agents in paper production or catalysts in bioplastics regularly results in toxic byproducts. Toxic wastewater is often dumped or needs to be purified in another industrial plant.

Shipping

Materials like paper, sugarcane bagasse, bioplastics and bamboo require extensive resource shipping. Paper production involves transporting raw timber, chemicals for pulping, and finishing materials across several facilities and countries. Bioplastics, bamboo and bagasse often rely on agricultural feedstocks (like corn or sugarcane) that are grown in one region, processed in another, and polymerized at additional facilities. Raw materials and intermediate products are transported globally before reaching the final production stage.

Disposal

“Compostable” materials like sugarcane bagasse, bamboo and some bioplastics are frequently sorted out in composting plants as they often don’t decompose into sellable compost or fertilizer. In addition, they often contain toxic materials like PFAS that poison compost and groundwater after disposal. Recycling doesn’t really work either. (Bio-)plastics and paper with food residues, coatings or multi-layers cannot be recycled. Energy and water consumption is very high and recycling always means downcycling – recycled paper and plastics are full of toxins and cannot be used in food contact.

Is recycling just wishcycling?

Is recycling just wishcycling?

Germany officially

30y

implementation of plastics recycling

30%

claimed recycled recycling quota for plastics

Germany in reality

<10%

of food-contaminated plastic & paper waste is truly recycled.*

Recycling is often seen as the ultimate solution, but it’s a system built on false promises. Food-contaminated plastics, coated paper, and multilayer packaging – over 80% of our waste – cannot be recycled. Even in advanced recycling systems like Germany’s, less than 10% of plastics are truly recycled, while the rest is burned, exported, or dumped. The industry promotes “wishcycling,” a feel-good concept where consumers hope their waste is recycled, but most ends up in landfills or oceans.

Recycling has been touted as a solution for nearly 40 years, yet plastic waste continues to rise. It's time to confront the truth: recycling, as it stands, cannot solve the problem of packaging waste.

Compostable materials succeed where recycling fails: they offer 100% efficiency, low costs, and no harmful emissions. And palm leaves are the rock stars of bioeconomy, because they break down seamlessly in any composting setting – industrial, home & natural.

Palm leaf

Palm leaves are the only material without raw material processing emissions.

Palm leaves compost naturally, anywhere, with zero waste or extra processing.

Palm leaf has a lower CO₂ footprint than paper even when shipped to the EU (1/4 world).

Comparison of disposable tableware materials

Comparison of disposable tableware materials

Environmental costs of conventional disposable tableware

Plastic

- fossil raw materials

- energy intensive production

- not-biodegradable

- microplastics in the food chain

- health risks (BPA)

- very low recycling quota

- recycling is very resource intense

Aluminium

- severe environmental

- damage from bauxite mining

- extremely energy-intensive production

- high manufacturing costs

- not-biodegradable

- harmful to health

- recycling is resource & emission intensive

Styrofoam

- fossil raw materials

- energy-intensive production

- not biodegradable

- uneconomical in recycling

- low recycling quota

- contains toxic chemicals

Paper

- slow growing raw material

- energy-intensive production

- not recycable with food

- resedues or coating

- harmful chemicals when bleached

- not heat and moisture resistant

- good recyclability without coating

- biodegradable

- renewable raw material

Environmental costs of alternative materials

Palm leaf

- natural by-product

- climate-neutral material

- home-compostable

- chemical-free

- longer transport routes to EU

Bioplastics

- Not all bio-based plastics are biodegradable

- not all biodegradable plastics are bio-based

- partly renewable raw materials, partly petroleum-based

- confusion over disposal

- competition for agricultural land

- can contaminate recycling streams

- often not home compostable

Bagasse

- by-product of sugar cane processing

- dependence on sugar production

- competition for agricultural land

- water intensive production

- long transport routes

- requires specialised composting facilities

- sustainable resources

- biodegradable

- need for composting facilities

Bamboo

- high production costs

- energy intensive production

- low resource consumption

- long transport routes to EU

- rapidly renewable raw material

- biodegradable

- need for composting facilities